Energy solution in the Carbon Neutral Era

Contents

Energy I. Wind Power Generation

1. ‘Carbon Neutral’ Era & Wind Power Generation: Status and trends

1) ‘Carbon Neutral’ Era & Wind Power Generation

a. ‘Carbon Neutral’ Era

· The most effective way to reduce carbon emissions is to reduce the carbon-intensive fossil fuel we can burn: Without energy transition, the operation of automobiles, aircrafts, and ships should be reduced by more than 90%, and the coal should be removed from the Earth.

b.RE100

· RE100 stands for 'Renewable Electricity 100%, and is an international campaign aimed at covering 100% of the electricity used by companies with renewable energy such as wind and solar power by 2050.

c. Energy transition → Contribution to CO2 reduction through Wind Power Generation

· Clean Energy Technology: Wind power generation has the highest potential for decarbonization per MW

· Energy conversion efficiency: 20~ 40% (vs. Sunlight 20%/ Biomass 20%/ Geothermal 10~20%)

· Levelized cost of electricity (LCOE): 1/4 compared to photovoltaic power generation

2) Global status of wind power generation –Global Wind Energy Council (GWEC)

a. Global wind power installations

· Cumulative global wind power installation by end of 2020: Total 743 GW (Onshore: 708GW, Offshore: 35GW)

- It helps the world to avoid over 1.1 billion tons of CO2 annually - equivalent to the annual CO2 emissions of South America.

- 93GW (Onshore: 74GW, Offshore: 8.2GW) of new wind power installations in 2020: a 53% growth compared to 2019 and 4times growth compared to 2010. It's expected to increase to 1TW in 2025

· Cumulative global wind power installation by end of 2021: Total 837 GW (Onshore: 780GW, Offshore: 57GW).93.6GW new wind power capacity was added. This brings total installed wind capacity to 837GW, a growth of 12.4% compared to 2020

Total global new wind power installations in 2021. Source: GWEC

Global wind power capacity has grown to 837GW in 2021· New wind power installations outlook

- GWEC Market Intelligence expects that over 469GW of new capacity will be added in the next 5 years (2020~2025)

· GWEC’s warning: this growth is not sufficient to ensure the world achieves net zero by 2050

- The new report published by the GWEC warns that the world needs to install new wind power capacity three times faster over the next decade to achieve net zero: the world needs to install up to 280 GW annually to maintain a pathway compliant with meeting net zero by 2050

Global wind power growth must triple over next decade

3) Trends

a. Innovation in rotor blade design and materials: bigger, better blades for wind turbine

· More power for generation from bigger blades

- In order to increase the efficiency of wind power generation, the material is changed to a light, strong, and stable structure with the enlargement of the blades

Future of Windex1) GE’s HALIADE-X 12MW with 220 m-rotor,107m-blade and 260m high

ex2) The World's Biggest Wind Turbines

- MingYang Smart Energy, a Chinese wind turbine manufacturer, is in the process of building the biggest wind turbine so far.: 16MW, Hight :264m, Blade Length:118m, Rotor Diameter:242m

- Simens Gamesa [SG 14-236DD] : 14MW, Blade Length:115m, Rotor Diameter:236m

- Vestas [V 236-15.0]: 15MW, Height: 280m,Blade Length:116m, Rotor Diameter:236m

- GE's [HALIADE-X]: 14MW, Height: 260m,Blade Length:107m, Rotor Diameter:220m

The World's Biggest Wind Turbines

지속가능한 기술.풍력발전이 나아갈 길

b. Rapid Growth of offshore wind

· Accelerating the growth of global offshore wind power generation

- Providing complementary alternatives to some of the problems encountered by onshore wind power deployment

- Global onshore outlook: The CAGR for onshore wind in the next 5year (2021~2025) is 0.3%. The average annual installation is 79.8GW, in total 399GW. On the other hand, the CAGR for offshore wind in the next 5year is 31.5%. In total more than 70GW offshore is expected to be added worldwide in 2021~2025.

- Offshore wind outlook to 2050: Global cumulative offshore wind capacity would increase almost ten-fold by 2030 (to 228 GW) and even more towards 2050, with total offshore installation nearing 1,000 GW by 2050.

- The replacement of old wind power facilities is expected to begin in the early 2030s and gradually increase from 2040

Future of Wind4) The problems of existing wind power generation systems

a. Noise Problem

· Problems caused by the enlargement of wind turbine blades for sufficient energy production

- The key factor of the noise caused by the wind turbine is aerodynamic factors: blade rotational noise

- In order to produce high output power, existing wind power generation systems with large blades mounted on top of steel towers at the high altitude with high with density and strong wind, generate serious noise.

- Increasing offshore wind installation to solve the noise problem caused by the enlargement of wind turbine blades.

b. Cost issue

· High equipment & construction, operation and grid connection costs

- The main cost factors of offshore wind power plants include turbines (including towers), substructure construction, grid connection and installation to the coast. Turbines are the largest cost components, accounting for up to 45% of all installation costs.

* Equipment & construction cost (Installation cost): High initial installation cost. Installing generators and blades on top of large steel towers, underwater construction work for fixing towers(substructure), and adding a grid connection platform. Offshore wind installation costs twice as much as that of onshore wind

* Operation cost: Due to the nature of high waves and wind exposure, offshore wind power systems need to be inspected, maintained, and repaired frequently

* Grid connection cost: Among wind power plant investment costs, the wind power system and grid connection cost is 9~14%, the second highest after the main facility cost

신재생에너지 현재와 미래

[Source : National Offshore Wind Energy Grid Interconnection Study Executive Summary, DOE award project]

[Source : National Offshore Wind Energy Grid Interconnection Study Executive Summary, DOE award project]

c. Problems of manufacturing, installing, durability, and lack of candidates for installation of large wind power facilities

· Blade manufacturing: advanced technologies in various fields required, such as aerodynamics, materials, and design

· Enlargement, weight lightening, and durability are the core of blade manufacturing technology

* Difficulty in installation: The longer turbine blade and the tower supporting it are too large and heavy to install

* Difficulty in manufacturing: As the rotating blades become longer and heavier, the power generation efficiency become decreased. Furthermore, it is difficult to make it possible to operate robust and flexible enough to withstand strong winds. The existing wind turbine blade manufacturing technology is not suitable for longer and larger blade manufacturing and less cost-effective.

* Durability problem: As the blade becomes longer and heavier, the high level of technologies to ensure structural stability and durability that can withstand long periods of time are required. Non-destructive testing of a wind turbine blade, wind turbine ice protection technology, sensor technology are essential to apply.

- The 3MW wind turbine blade weighs about 10 tons and the tip of the blade rotates at a speed of 250 km/h. If the airfoil shape can’t be retained, it can interfere with the overall wind power generating performance.

- Load reduction is important as the blade size increases, but with respect to the shape (airfoil), structural rigidity (thickness of the blade) needs to be prioritized even if the lift coefficient is slightly sacrificed.

- The recent R&D focus of wind turbine blade technology: maintaining the light weight and high rigidity of wind turbine blade, while increasing the reliability and energy efficiency. The constituent materials upgrade, efficient design technology development, and test technology development are necessary to this end.

d. Others

· Energy efficiency that varies depending on geographic limitations and climate conditions(intermittent)

- Difficulty in the accurate prediction of energy production

- Best available wind sites are limited

- Integrating energy storage technology on the wind generating system to enhance grid safety is needed

· Negative effects on the surrounding ecological environment

- Birds and bats hit the rotating longer blades and threatened by their survival.

2. New wind power system

1) Overview

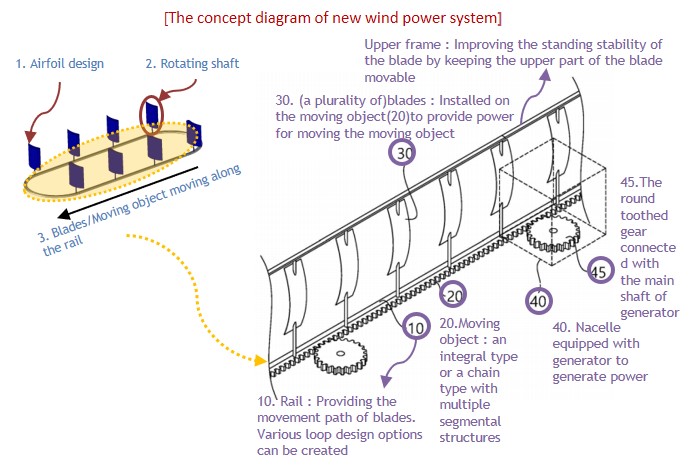

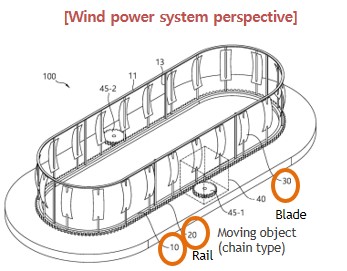

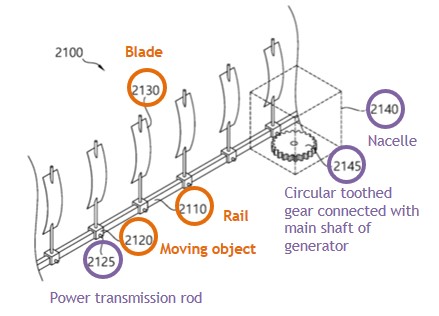

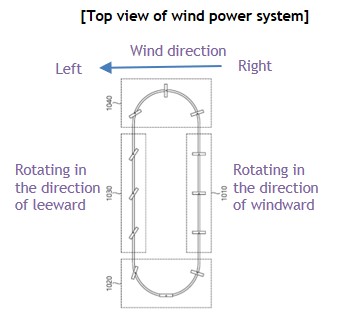

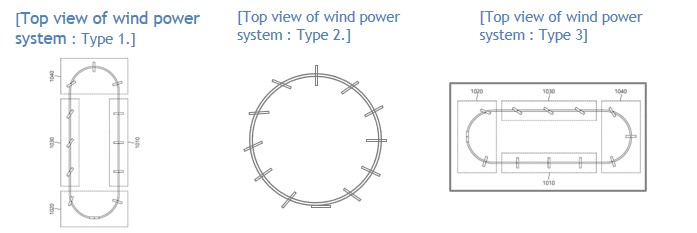

a. Wind power generation system using multiple blades and rail

· Patent Application Number (Korea) : 10-2020-0045176 / 10-2020-0045177

- The main shaft of the generator is configured to rotate using the movement of the moving object and/or blade designed as a plurality of airfoil shape and moving along the movement path provided by the rail.

- A wind power generation system capable of "solving the noise problem" comes from the high-speed rotation of existing large wind turbine blades.

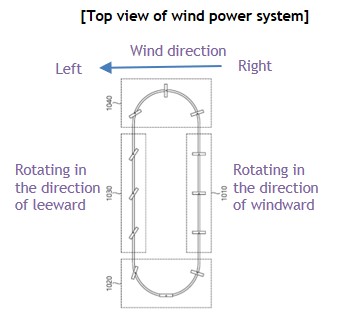

- The rail forms a loop, and the plurality of blades is configured to adaptively rotate to maximize power for the target movement direction, based on information on a target movement direction determined by each position in the loop and information on a wind direction

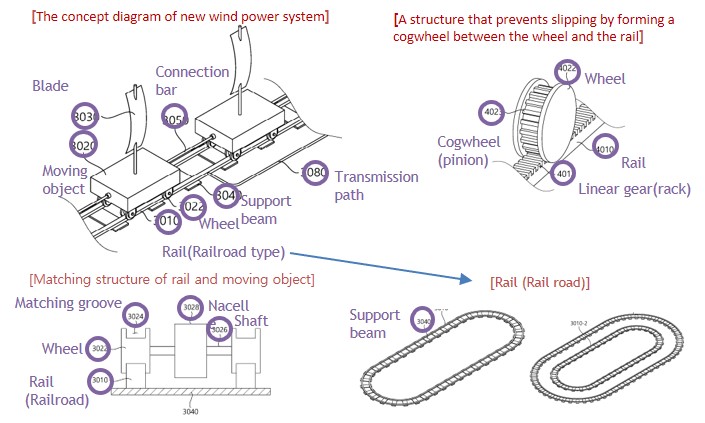

b. Wind power generation system using multiple blades and train rails: The concept expansion from the system 1 (PCT Number 10-2020-0045176 / 10-2020-0045177)

· Patent Application Number (Korea) : 10-2021-0054133 / 10-2021-0054135

- The main shaft of the generator is configured to rotate using the movement of the moving object and/or blade designed as a plurality of airfoil shape and moving along the movement path provided by the rail.

- A wind power generation system capable of "solving the noise problem " comes from the high-speed rotation of existing large wind turbine blades.

- The rail forms a loop, and the plurality of blades are configured to adaptively rotate to maximize power for the target movement direction based on information on a target movement direction determined by each position in the loop and information on a wind direction.

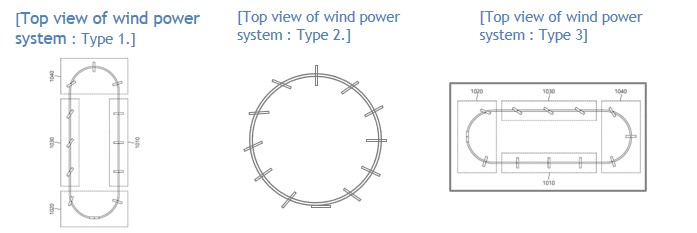

2) Basic configuration

a. Rail

· Function

- Providing a movement path of a plurality of blades. The rail forms a loop and a plurality of blades moves along the loop.

- Various loop design options can be created

b. Moving object

· Function

- A component that slides and moves along the movement path provided by the rail. It moves with blades together.

· Structure

- Design types: an integral type or a chain type with multiple segmental structures

c. Blade

· Material

- Blades are made of thin film type of materials or flexible materials.

· Function

- Power provision: Blades are installed on the moving object and provide the power made with wind to the moving object for its movement.

- Location determination: The device for receiving location information is provided for each blade.

- Wind direction data collection: Each blade can have a wind direction sensor for collecting wind direction data. Or each loop has one sensor.

- Acquisition of wind speed information: Device that measure wind speed can be installed for each blade or each loop. This device calculates the estimated moving speed of the loop.

- Orientation determination: performing operations necessary for orientation determination of rotating blades with the computer device or processor

· Other Systems: Control systems & protective devices can be located on the loop constituted by blades or rail

- Control system: An integrated control system configured to transmit and receive information with blades. Performing control on each blade. The installation location of each blade and the distance between blades can be changed and adjusted on the moving object.

- Protection device: equipped on the loop against weather deterioration, typhoon, and etc.

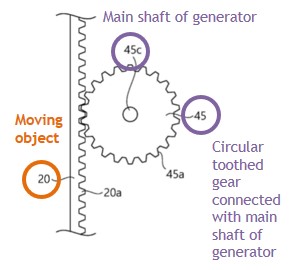

d. Nacelle

· Nacelle equipped with the generator that generates electricity

- The generator is configured to have a predetermined target rotational speed.

· Function

- A power generation device that converts rotational force obtained from a blade into electrical energy. The power transmission structure among each blade, the moving object and the main shaft of generator is the same as the image. The main shaft of the generator rotates in conjunction with the movement of the moving object. Electricity is generated by the rotating main shaft of generator.

- A plurality of nacelles can be installed: A separate nacelle including an additional generator can be further provided.

3. References

1) Evaluation report - new wind power system (March 2020, Pohang University of Science and Technology)

· As a result of comparative research with existing wind turbines, similar or “higher energy output and noise reduction” were confirmed

· Methodology

- Utilization of Computational Fluid Dynamics (CFD). Measuring energy generated by multiple blades moving on the rail in a straight-line area and comparing with the efficiency of existing wind power systems.

· Analysis conditions

- Whole calculation area: 300 x 250 x 200 (m³)

- The size of blade(airfoil): Horizontal length = 90 (m)/Vertical height = 120 (m)/Maximum incident angle = 5.5 degrees/Distance between blades = 150 (m)/Rail moving speed = 1.9 m/s (based on generator maximum efficiency)

- Generator attribute: NREL's 5MW gearbox model having an energy conversion efficiency of 94.4%. The gear is connected to the rail to transmit torque to the main shaft of the generator or nacelle.

- Existing wind power generator size: Rotor diameter 77m / NREL’s EMD turbine installed in Gasiri, Jeju

· Analysis Results

- In the case of individual turbines receiving tailwinds, similar or higher output can be expected from existing general-purpose wind turbines.

- If the wind direction is changed to headwind, a sharp reduction in power is found. However, if the new wind power system adaptively receives maximum power from the rotating blades according to the wind direction, the problem of power reduction could be resolved.

-The structure is simpler than that of existing wind turbines, so if a larger turbine (more than 5MW model) is used, the output can be expected to improve.

- The most positive research results: The biggest strength is noise reduction. Pressure loss related to noise generation is about 1/65 of the existing turbine. (Reference: Li et al., 2020, Renewable Energy)

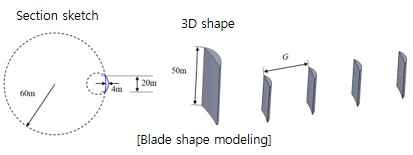

2) Interpretation of a new wind power system using a sail-type structure.

- In June 2020, Ulsan Institute of Science and Technology, Department of Mechanical Aviation and Nuclear Engineering.

· It was discovered that the new wind power generation system could show “power generation efficiency similar to that of existing wind power generators”

· Research methods and goals

- Development of a flow analysis module for the analysis of a wind power generation system using a plurality of blades

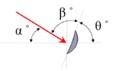

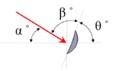

- The goal is to derive optimal shapes and parameters capable of maximizing energy efficiency compared to existing wind power. Parameter types [Wind angle (α), blade angle (θ), distance between blades (G)]

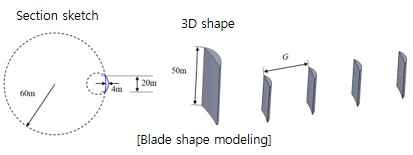

· Blade shape modeling

- A cross section of a blade shape (crescent moon) [(height: 50 m, width: 20 m, area: 1,000 m2)]

- 4 Blades installed (Total area size: 4,000m²)

· The angle between wind and blade: β=180-(α+θ) ˚

* The wind becomes perpendicular to the suction side of the blade at β ≈90˚

* The wind becomes parallel to the blade shape at β ˚≈180° or 0°

· Analysis result

- When the wind angle (α) is fixed, there is a maximum thrust value at a specific blade angle.

- At all G (distance between blades), maximum thrust (Fx|max) occurs at (α = 60°, β = 30°)

* The maximum thrust of blades (Fx|max) -524kN (G = 25m, α = 60˚, θ = 90˚; Refer to p. 22)

* The maximum thrust of blades (Fx|max) -533kN (G = 50m, α = 60˚, θ = 90˚; Refer to p. 10)

* The maximum thrust of blades (Fx|max) -550kN (G = 100m, α = 60˚, θ = 90˚; Refer to p. 35)

- Increasing power generation efficiency when the distance between blades (G) decreases (blade integration increases): In this study, when G is 25m, it shows similar efficiency to existing conventional wind power generators (G=25m: 34.7%, G=50m: 21.6%, G=100m: 12.7%).

- With the optimal parameter suggested in this study, the new wind power system can show similar power generation efficiency to the existing wind power generator.

(Reference) The theoretical efficiency of wind power generators is limited to 59.26 % (Betz’s limit). The actual efficiency is reported to be about 35 to 40% (Ragheb & Ragheb 2011)

4. The expectations from new wind power system

1) Noise Control

· A wind power system in which a plurality of blades moves on a rail and rotates the shaft of generator

- Wind power generation system that doesn’t require large blades and high-speed rotors

· Design considering the lightweight and aerodynamic structure of blades: sail-shaped blades without rotating longer blades

· Wind power system that doesn't require a high-speed rotor.

a. Power generation method: A power generation method using rails and multiple blades.

- The shaft of the generator is configured to rotate using the movement of a plurality of blades and moving object moving along the movement path provided by the rail.

b. Design and material: A sail-shaped blade without a rotating loner blade. Thin film materials with air pockets.

- Without a high-speed rotor, a plurality of blades made of thin film materials rotates on the rail. Sensing wind conditions, the blade rotates in the direction where thrust can be at its maximum. Even under low wind speed conditions, it’s possible to secure movement and power in the desired direction.

2) Cost Reduction

· Simple structural wind power system that does not require large-scale manufacturing and construction work

· Manufacturing & Construction cost: manufacturing and installation process without large-scale construction work. land acquisition cost also can be reduced

· Management & operating cost: Simple structural system easy to manage

· Grid connection cost: high accessible site selection and infrastructure cost reduction are available

a. Manufacturing/Construction cost: Bigger & longer blade manufacturing, steel tower & underwater substructure construction, and large site acquisition cost are reduced

- A simple structural system, multiple blades installed on the rail without manufacturing a large steel tower over 200m and underwater substructure work.

- Blade manufacturing: A shape similar with a sail on a sailing yacht. Each blade made of thin film type of materials is maintained by a support beam. It can be made of special lightweight materials. Hemp cloth, cotton cloth, synthetic fibers such as tetron, or polymer fusion can be used.

- Site purchase cost reduction: When a wind farm for large amounts of power generation is configured, space efficiency is higher than that of existing wing rotation wind power generators.

b. Management & operating cost: omitting the complex operation & management process required for existing offshore wind power generation facilities installed in the distant sea

- In order to inspect the offshore wind farm, it is necessary to move by boat from land. And considerable management costs are required due to the high waves and wind exposure of wind power generation facilities. Free from the lack of technology, manpower, and infrastructure necessary for maintenance and repair.

c. Grid connection cost: free from the location restriction

- Saving the infrastructure cost to draw electricity from existing large generators installed in the distant sea: Eliminating the need for long cables, power connection platforms, etc., and saving related infrastructure costs

3) Power generation efficiency improvement

· A wind power system designed to optimally respond to changes in wind direction and wind density

- A plurality of blades detects wind conditions and rotate themselves in the direction where thrust can be increased the most

- Without a high-speed rotor, securing movement and power in the desired direction even in low wind speed conditions

· Blade rotation in the direction favorable to thrust increase

· Blade shape deformation

a. Blade rotation in the direction favorable to thrust increase

- Optimal response to changes in wind direction and density: When the target movement direction is determined according to the position of each blade, the orientation of the blade can be changed by rotating the blades themselves in consideration of the wind direction favorable to thrust increase.

- Each blade rotates in the direction of leeward when the target movement direction coincides with the wind direction.

- Each blade rotates in the direction of windward when the target movement direction is opposite to the wind direction

b. Blade shape deformation

· It is possible to transform each blade to have a shape that maximizes the power in the target movement direction

- Utilization of the characteristics of blade material: Each blade could be made of flexible materials with an air pocket, and by using this, each blade can be transformed into the blade shape that can maximize power by controlling the amount of air charged.

- It can be configured to be deformed into the shape that maximizes power in the target movement direction by selectively controlling the amount of air charged for at least one of air pockets. In this case, an air pump may be used to change the amount of air charged.

- If the blade is in the form of a thin film without an air pocket, it can be controlled by a grid-type support that can change the angle in each grid unit: The blade could be deformed into a shape that maximizes power according to given wind conditions by changing the angle of rotation in each grid unit.

4) Advantageous to make the blade bigger

· Wind power system that easily to make the blade bigger to expand power generation capacity

· Due to the design and material characteristics of the blade, it’s easy to make it bigger than that of the existing wind power system

· Maximizing power generation efficiency

a. Advantageous for expanding power generation capacity as the blade become bigger

- Due to the design and material characteristics of the blade, it is easy to manufacture it bigger than that of the existing wind power system: Power generation capacity can be increased as the blade become bigger. Free from wind density restrictions, and high-speed turbines need not anymore.

- Currently, wind power blade manufacturing technology is at a blade length around 120m, in particular, has a difficulty in making the blade tip thicker to reduce noise.

- In the simulation research, the blade size was 20m*50m and 90m*120m. However, considering material characteristics of the blade, it is easy to make the height of 500m and 1,000m or more.

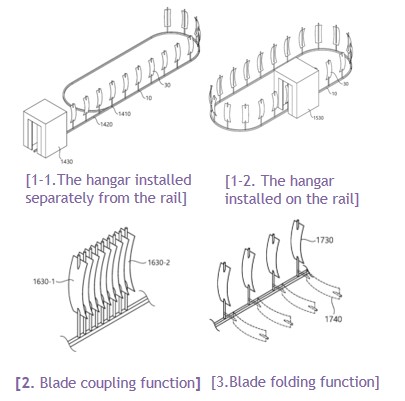

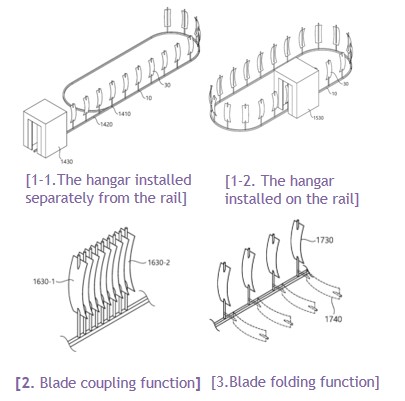

5) Improving the safety of wind power generation facility

· Simple structural wind power system doesn’t require large-scale wind turbine blade manufacturing and construction work

· Minimizing the risk of collision with birds

· Countermeasures against bad weather (typhoons, heavy rain and wind)

a. Improving the safety of facilities

- Minimizing the risk of collision with birds

b. Countermeasures against the facility destruction from bad weather

- Protection device: Blade protection device [hangar] installed on the rail

*Separate construction from the rail

*Construction on a rail

- Blade coupling function: In case of bad weather, blades are combined.

- Blade folding function: In case of bad weather, the blade is folded in the ground direction.

6) Minimizing of location restrictions and having a variety of uses

· Free from the constraints of physical space. Suitable for sustainable power supply in the carbon neutral era

· System can be built in any terrain conditions

· Advantageous for Wind Farm configuration

a. Customized rail design is available for terrain and wind conditions

- Rails can be installed in any terrain condition as long as the wind density is high

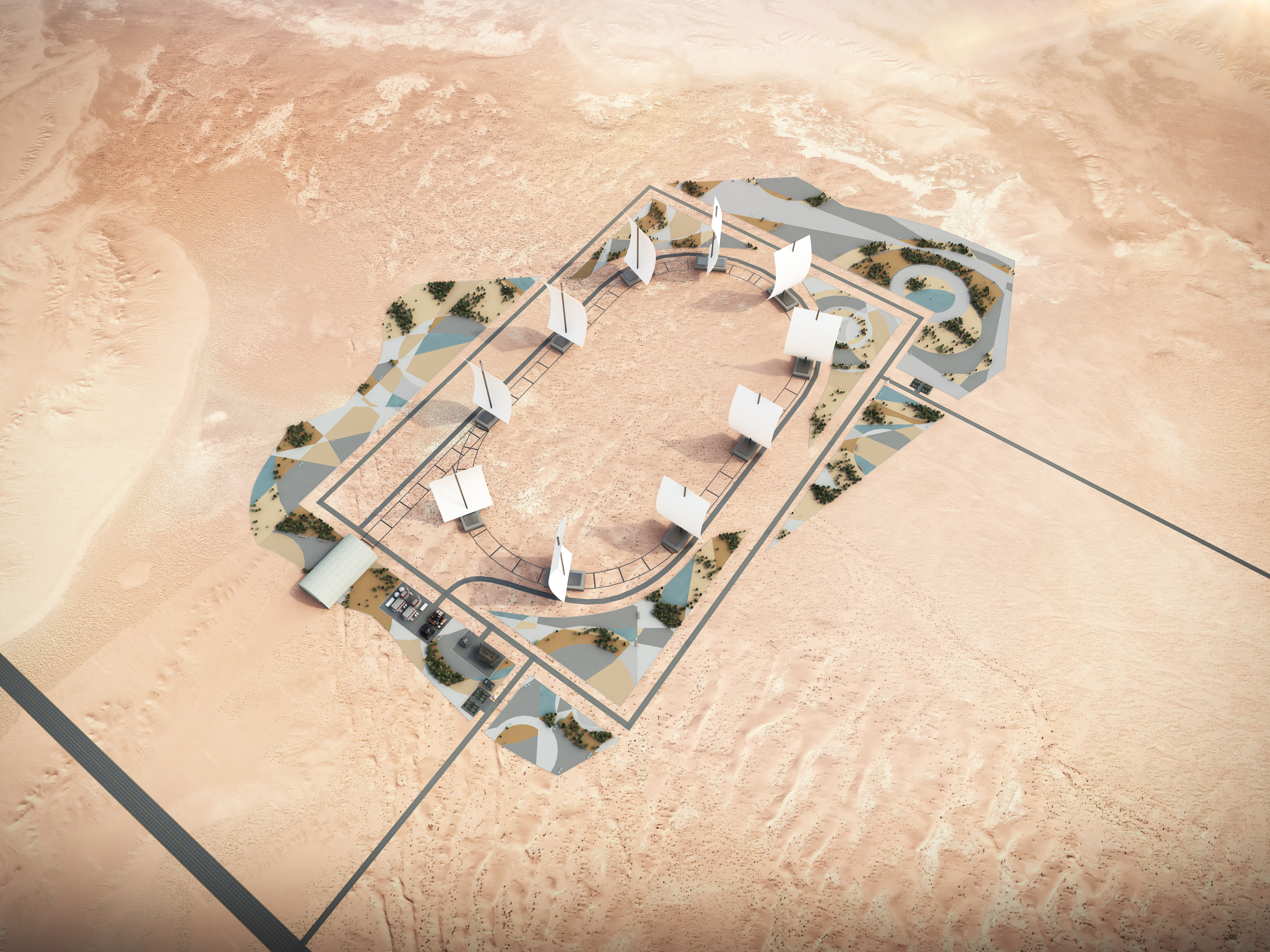

- When rails are installed on the ground with support(beams), horizontal movement paths are provided regardless of topographic conditions: rails can be installed in the middle of the desert without restrictions on places such as high mountains, flatlands, coasts, and etc.

- Even if it is not a complete horizontal level of flat land, rails can be applied to terrain with approximate slopes and curves except that of vertical direction

- Various rail designs available: Rail designs can be made in various forms, such as circular and oval shapes, depending on the wind power system installation target terrain and wind conditions.

b. Advantageous for Wind Farm Configuration: Sustainable high-capacity power supply

- High spatial efficiency and ease of installation: Possible to develop nationwide large wind power generation complexes for Net-Zero emissions.

- Compared to the existing wind power system with large rotating wing, it is advantageous for configuring huge wind farms capable of mass production of electricity.

- Sustainable power supply can be promoted through the construction of a nationwide large wind farm across the country in areas with high wind density such as the Atlantic coast, the Gobi Desert and etc.

ex) Building a wind farm in the Gobi Desert: the enough amount of energy for the whole world or entire continent to use can be generated and supplied

5. The aerial view of wind farm

Energy II. Agrophotovoltaics

1. Overview

1) Energy – Agrophotovoltaics :Combining Photosynthesis & Photovoltaics

- A convergence system that can produce electricity by building up solar panels on existing farmland, while preserving farmland in one piece and sustain the harvest of crops as well.

- The system is believed to contribute to increasing income of farming households, importantly along with expanding the spread of new·renewable energy.

2) Light saturation point

- [Light saturation point (LSP)]: Each plant has a certain amount of light it needs to grow well. Sunlight over that amount is not needed.

- Any light past the Light saturation point (LSP) causes harm.

- Agrophotovoltaics know as agricultural solar sharing uses the extra sun energy that would otherwise to wastes or be harmful to the plants.

3) Energy Generation + Crop Harvest

- By way of installing solar panels at such a height as not to obstruct the operation or transportation of agricultural machineries and placing them with such an enough spacing as to ensure sufficient sunshine for the crops to grow, the crop yield shall be kept no less than those before the construction

4) Significance: presenting new direction of new & renewable energy business

- This is an eco-saving technology which enables to produce and sell the electricity at the same time as harvesting of crops, thereby contributing not only to the improvement of the incomes of farming households but also to the efficient utilization of scarce land all over the world.

2. Agrophotovoltaics & Agriculture

1) Food Crisis & Instability in agricultural work

- Food Crisis

* The growing global population, coupled with the shortage of arable land, could mean that we’re heading for a food crisis in the future.

- Instability

* Farming is different from other jobs because it can be hard to predict production amounts.: The weather is greatly influencing crops, and crop yield is directly linked to livelihood. There is also the problem of not getting any income if the crops that were harvested couldn’t be sold

2) Benefits from Agrophotovoltaics (Solar sharing) system

· A great way to solve the shortage of arable land and the problem of instability in agricultural work

- Increased land productivity

* The dual use of land for the harvesting of solar electricity and agriculture has been test and showed the land use efficiency of 160 percent in 2017 and 186 percent in 2018

- Improved water efficiency of land: positive results in using solar panels on farmland

* In 2018, experts from Oregon State’s College of Agricultural Sciences revealed the results of a study showing that solar modules could increase agricultural production on dry and unirrigated land.

* The soil beneath the panels had higher levels of moisture than the soil exposed directly to the sun.

* Reduced need for irrigation

- Stabilized and increased Profit

* Profit is further stabilized by adding income from energy produced and sold (or locally used) to income from agriculture.

* With this added income, it makes it easier to become established as a full-time farmer. Furthermore, by becoming a full-time farmer, more time can be used for making high quality crops.

- Prepare a good cultivation environment

* Key solution to reduce the need of time-consuming and labor cost and improve an uncomfortable labor environment

ex) installing an automatic fertilizer as part of the solar sharing frame, which could be programmed each season

- In June 2020, Ulsan Institute of Science and Technology, Department of Mechanical Aviation and Nuclear Engineering.

· It was discovered that the new wind power generation system could show “power generation efficiency similar to that of existing wind power generators”

· Research methods and goals

- Development of a flow analysis module for the analysis of a wind power generation system using a plurality of blades

- The goal is to derive optimal shapes and parameters capable of maximizing energy efficiency compared to existing wind power. Parameter types [Wind angle (α), blade angle (θ), distance between blades (G)]

· Blade shape modeling

- A cross section of a blade shape (crescent moon) [(height: 50 m, width: 20 m, area: 1,000 m2)]

- 4 Blades installed (Total area size: 4,000m²)

· The angle between wind and blade: β=180-(α+θ) ˚

* The wind becomes perpendicular to the suction side of the blade at β ≈90˚

* The wind becomes parallel to the blade shape at β ˚≈180° or 0°

· Analysis result

- When the wind angle (α) is fixed, there is a maximum thrust value at a specific blade angle.

- At all G (distance between blades), maximum thrust (Fx|max) occurs at (α = 60°, β = 30°)

* The maximum thrust of blades (Fx|max) -524kN (G = 25m, α = 60˚, θ = 90˚; Refer to p. 22)

* The maximum thrust of blades (Fx|max) -533kN (G = 50m, α = 60˚, θ = 90˚; Refer to p. 10)

* The maximum thrust of blades (Fx|max) -550kN (G = 100m, α = 60˚, θ = 90˚; Refer to p. 35)

- Increasing power generation efficiency when the distance between blades (G) decreases (blade integration increases): In this study, when G is 25m, it shows similar efficiency to existing conventional wind power generators (G=25m: 34.7%, G=50m: 21.6%, G=100m: 12.7%).

- With the optimal parameter suggested in this study, the new wind power system can show similar power generation efficiency to the existing wind power generator.

(Reference) The theoretical efficiency of wind power generators is limited to 59.26 % (Betz’s limit). The actual efficiency is reported to be about 35 to 40% (Ragheb & Ragheb 2011)

4. The expectations from new wind power system

1) Noise Control

· A wind power system in which a plurality of blades moves on a rail and rotates the shaft of generator

- Wind power generation system that doesn’t require large blades and high-speed rotors

· Design considering the lightweight and aerodynamic structure of blades: sail-shaped blades without rotating longer blades

· Wind power system that doesn't require a high-speed rotor.

a. Power generation method: A power generation method using rails and multiple blades.

- The shaft of the generator is configured to rotate using the movement of a plurality of blades and moving object moving along the movement path provided by the rail.

b. Design and material: A sail-shaped blade without a rotating loner blade. Thin film materials with air pockets.

- Without a high-speed rotor, a plurality of blades made of thin film materials rotates on the rail. Sensing wind conditions, the blade rotates in the direction where thrust can be at its maximum. Even under low wind speed conditions, it’s possible to secure movement and power in the desired direction.

2) Cost Reduction

· Simple structural wind power system that does not require large-scale manufacturing and construction work

· Manufacturing & Construction cost: manufacturing and installation process without large-scale construction work. land acquisition cost also can be reduced

· Management & operating cost: Simple structural system easy to manage

· Grid connection cost: high accessible site selection and infrastructure cost reduction are available

a. Manufacturing/Construction cost: Bigger & longer blade manufacturing, steel tower & underwater substructure construction, and large site acquisition cost are reduced

- A simple structural system, multiple blades installed on the rail without manufacturing a large steel tower over 200m and underwater substructure work.

- Blade manufacturing: A shape similar with a sail on a sailing yacht. Each blade made of thin film type of materials is maintained by a support beam. It can be made of special lightweight materials. Hemp cloth, cotton cloth, synthetic fibers such as tetron, or polymer fusion can be used.

- Site purchase cost reduction: When a wind farm for large amounts of power generation is configured, space efficiency is higher than that of existing wing rotation wind power generators.

b. Management & operating cost: omitting the complex operation & management process required for existing offshore wind power generation facilities installed in the distant sea

- In order to inspect the offshore wind farm, it is necessary to move by boat from land. And considerable management costs are required due to the high waves and wind exposure of wind power generation facilities. Free from the lack of technology, manpower, and infrastructure necessary for maintenance and repair.

c. Grid connection cost: free from the location restriction

- Saving the infrastructure cost to draw electricity from existing large generators installed in the distant sea: Eliminating the need for long cables, power connection platforms, etc., and saving related infrastructure costs

3) Power generation efficiency improvement

· A wind power system designed to optimally respond to changes in wind direction and wind density

- A plurality of blades detects wind conditions and rotate themselves in the direction where thrust can be increased the most

- Without a high-speed rotor, securing movement and power in the desired direction even in low wind speed conditions

· Blade rotation in the direction favorable to thrust increase

· Blade shape deformation

a. Blade rotation in the direction favorable to thrust increase

- Optimal response to changes in wind direction and density: When the target movement direction is determined according to the position of each blade, the orientation of the blade can be changed by rotating the blades themselves in consideration of the wind direction favorable to thrust increase.

- Each blade rotates in the direction of leeward when the target movement direction coincides with the wind direction.

- Each blade rotates in the direction of windward when the target movement direction is opposite to the wind direction

b. Blade shape deformation

· It is possible to transform each blade to have a shape that maximizes the power in the target movement direction

- Utilization of the characteristics of blade material: Each blade could be made of flexible materials with an air pocket, and by using this, each blade can be transformed into the blade shape that can maximize power by controlling the amount of air charged.

- It can be configured to be deformed into the shape that maximizes power in the target movement direction by selectively controlling the amount of air charged for at least one of air pockets. In this case, an air pump may be used to change the amount of air charged.

- If the blade is in the form of a thin film without an air pocket, it can be controlled by a grid-type support that can change the angle in each grid unit: The blade could be deformed into a shape that maximizes power according to given wind conditions by changing the angle of rotation in each grid unit.

4) Advantageous to make the blade bigger

· Wind power system that easily to make the blade bigger to expand power generation capacity

· Due to the design and material characteristics of the blade, it’s easy to make it bigger than that of the existing wind power system

· Maximizing power generation efficiency

a. Advantageous for expanding power generation capacity as the blade become bigger

- Due to the design and material characteristics of the blade, it is easy to manufacture it bigger than that of the existing wind power system: Power generation capacity can be increased as the blade become bigger. Free from wind density restrictions, and high-speed turbines need not anymore.

- Currently, wind power blade manufacturing technology is at a blade length around 120m, in particular, has a difficulty in making the blade tip thicker to reduce noise.

- In the simulation research, the blade size was 20m*50m and 90m*120m. However, considering material characteristics of the blade, it is easy to make the height of 500m and 1,000m or more.

5) Improving the safety of wind power generation facility

· Simple structural wind power system doesn’t require large-scale wind turbine blade manufacturing and construction work

· Minimizing the risk of collision with birds

· Countermeasures against bad weather (typhoons, heavy rain and wind)

a. Improving the safety of facilities

- Minimizing the risk of collision with birds

b. Countermeasures against the facility destruction from bad weather

- Protection device: Blade protection device [hangar] installed on the rail

*Separate construction from the rail

*Construction on a rail

- Blade coupling function: In case of bad weather, blades are combined.

- Blade folding function: In case of bad weather, the blade is folded in the ground direction.

6) Minimizing of location restrictions and having a variety of uses

· Free from the constraints of physical space. Suitable for sustainable power supply in the carbon neutral era

· System can be built in any terrain conditions

· Advantageous for Wind Farm configuration

a. Customized rail design is available for terrain and wind conditions

- Rails can be installed in any terrain condition as long as the wind density is high

- When rails are installed on the ground with support(beams), horizontal movement paths are provided regardless of topographic conditions: rails can be installed in the middle of the desert without restrictions on places such as high mountains, flatlands, coasts, and etc.

- Even if it is not a complete horizontal level of flat land, rails can be applied to terrain with approximate slopes and curves except that of vertical direction

- Various rail designs available: Rail designs can be made in various forms, such as circular and oval shapes, depending on the wind power system installation target terrain and wind conditions.

b. Advantageous for Wind Farm Configuration: Sustainable high-capacity power supply

- High spatial efficiency and ease of installation: Possible to develop nationwide large wind power generation complexes for Net-Zero emissions.

- Compared to the existing wind power system with large rotating wing, it is advantageous for configuring huge wind farms capable of mass production of electricity.

- Sustainable power supply can be promoted through the construction of a nationwide large wind farm across the country in areas with high wind density such as the Atlantic coast, the Gobi Desert and etc.

ex) Building a wind farm in the Gobi Desert: the enough amount of energy for the whole world or entire continent to use can be generated and supplied

- The system is believed to contribute to increasing income of farming households, importantly along with expanding the spread of new·renewable energy.

2) Light saturation point

- [Light saturation point (LSP)]: Each plant has a certain amount of light it needs to grow well. Sunlight over that amount is not needed.

- Any light past the Light saturation point (LSP) causes harm.

- Agrophotovoltaics know as agricultural solar sharing uses the extra sun energy that would otherwise to wastes or be harmful to the plants.

3) Energy Generation + Crop Harvest

- By way of installing solar panels at such a height as not to obstruct the operation or transportation of agricultural machineries and placing them with such an enough spacing as to ensure sufficient sunshine for the crops to grow, the crop yield shall be kept no less than those before the construction

4) Significance: presenting new direction of new & renewable energy business

- This is an eco-saving technology which enables to produce and sell the electricity at the same time as harvesting of crops, thereby contributing not only to the improvement of the incomes of farming households but also to the efficient utilization of scarce land all over the world.

2. Agrophotovoltaics & Agriculture

1) Food Crisis & Instability in agricultural work

- Food Crisis

* The growing global population, coupled with the shortage of arable land, could mean that we’re heading for a food crisis in the future.

- Instability

* Farming is different from other jobs because it can be hard to predict production amounts.: The weather is greatly influencing crops, and crop yield is directly linked to livelihood. There is also the problem of not getting any income if the crops that were harvested couldn’t be sold

2) Benefits from Agrophotovoltaics (Solar sharing) system

· A great way to solve the shortage of arable land and the problem of instability in agricultural work

- Increased land productivity

* The dual use of land for the harvesting of solar electricity and agriculture has been test and showed the land use efficiency of 160 percent in 2017 and 186 percent in 2018

- Improved water efficiency of land: positive results in using solar panels on farmland

* In 2018, experts from Oregon State’s College of Agricultural Sciences revealed the results of a study showing that solar modules could increase agricultural production on dry and unirrigated land.

* The soil beneath the panels had higher levels of moisture than the soil exposed directly to the sun.

* Reduced need for irrigation

- Stabilized and increased Profit

* Profit is further stabilized by adding income from energy produced and sold (or locally used) to income from agriculture.

* With this added income, it makes it easier to become established as a full-time farmer. Furthermore, by becoming a full-time farmer, more time can be used for making high quality crops.

- Prepare a good cultivation environment

* Key solution to reduce the need of time-consuming and labor cost and improve an uncomfortable labor environment

ex) installing an automatic fertilizer as part of the solar sharing frame, which could be programmed each season

- Any light past the Light saturation point (LSP) causes harm.

- Agrophotovoltaics know as agricultural solar sharing uses the extra sun energy that would otherwise to wastes or be harmful to the plants.

4) Significance: presenting new direction of new & renewable energy business

- This is an eco-saving technology which enables to produce and sell the electricity at the same time as harvesting of crops, thereby contributing not only to the improvement of the incomes of farming households but also to the efficient utilization of scarce land all over the world.

2. Agrophotovoltaics & Agriculture

1) Food Crisis & Instability in agricultural work

- Food Crisis

* The growing global population, coupled with the shortage of arable land, could mean that we’re heading for a food crisis in the future.

- Instability

* Farming is different from other jobs because it can be hard to predict production amounts.: The weather is greatly influencing crops, and crop yield is directly linked to livelihood. There is also the problem of not getting any income if the crops that were harvested couldn’t be sold

2) Benefits from Agrophotovoltaics (Solar sharing) system

· A great way to solve the shortage of arable land and the problem of instability in agricultural work

- Increased land productivity

* The dual use of land for the harvesting of solar electricity and agriculture has been test and showed the land use efficiency of 160 percent in 2017 and 186 percent in 2018

- Improved water efficiency of land: positive results in using solar panels on farmland

* In 2018, experts from Oregon State’s College of Agricultural Sciences revealed the results of a study showing that solar modules could increase agricultural production on dry and unirrigated land.

* The soil beneath the panels had higher levels of moisture than the soil exposed directly to the sun.

* Reduced need for irrigation

- Stabilized and increased Profit

* Profit is further stabilized by adding income from energy produced and sold (or locally used) to income from agriculture.

* With this added income, it makes it easier to become established as a full-time farmer. Furthermore, by becoming a full-time farmer, more time can be used for making high quality crops.

- Prepare a good cultivation environment

* Key solution to reduce the need of time-consuming and labor cost and improve an uncomfortable labor environment

ex) installing an automatic fertilizer as part of the solar sharing frame, which could be programmed each season

ex) The solar panels overhead create shade as a thermal insulator for the laborers working with the crops making it a more bearable environment to work in.

- Making the farm completely energy-independent

* Farmers will no longer be surprised by unexpected power failures, since the energy captured from sunlight will be stored using batteries, making the farm completely energy-independent.

- Additional benefits

* Protection against damage caused by hail, drought and frost

3) Reference

영농형 태양광-자원 효율적 토지이용 [Agrophotovoltaics · Resource Efficient Land Use (APV-RESOLA)]

· Over the past two years, the dual use of land for the harvesting of solar electricity and agriculture has been tested in the joint project of Fraunhofer ISE.

- On one-third of a hectare arable land near Lake Constance in Germany, photovoltaic modules with a total power output of 194 kilowatt are installed on a five-meter-high structure.

- The results from 2017 showed a land use efficiency of 160 percent, as confirmed by the project consortium.

- The performance of the agrophotovoltaic system in the very hot summer of 2018 greatly exceeded this value.: Based on the 2018 potato yield, the land use efficiency rose to 186 percent per hectare with the agrophotovoltaic system -by Stephan Schindele of Fraunhofer ISE

· Scientists of the University of Hohenheim collected data on the climatic conditions underneath the APV system and also from the neighboring reference field.

- The solar irradiation underneath the APV system was about 30 percent less than the reference field. In addition to the amount of solar irradiation, the APV system affects the distribution of precipitation and the soil temperature.

- In spring and summer, the soil temperature under the APV system was less than on the reference field; the air temperature was identical.

- In the hot, dry summer of 2018, the soil moisture in the wheat crop was higher than the reference field, while in the winter months, it was less.

* The shade under the semi-transparent solar modules enabled the plants to better endure the hot and dry conditions of 2018 -the agricultural scientist Andrea Ehmann

* This result shows the potential for APV in arid regions.

- The electricity production costs of an APV system is today competitive with a small PV rooftop system. Researchers anticipate further cost reductions due to economies of scale and learning effects.

- If the electricity is stored and used on site, as at the farm community Heggelbach, additional sources of income arise due to synergy effects.

- When politics allow, agrophotovoltaics can provide the answer to the “food or fuel” debate. From the technical point of view, farmers can harvest both.

- Through the dual use of arable land, the main task of food production is met. The additional solar electricity production contributes to the expansion of electric mobility and serves to protect the climate.

3. Agrophotovoltaics & Energy

1) Global Energy Solution

· Earth friendly energy

- Energy generation without carbon emissions

- Shade from the panels protects against overheating and global warming, also keeps the earth humid.

· Effective Energy: there is little sunlight wasted.

- Most crops need light to grow. However, plants don’t expend all the light they take in from the sun. Each plant has its own limit to how much sunlight it can take in, and if it goes over that limit it is wasted, or hurts the plant. Agrophtoboltaics (Solar sharing) is used to take in the sunlight that would otherwise go to waste or otherwise harm the plants and turns it into usable electricity.

· Sustainable Energy

- An effective way to produce sustainable energy without devastating the environment

- This system enables people to generate electricity on farmland, pasture land, water surfaces, roads, and anywhere people, animals, and plants are living.

- Even barren deserts can be changed into habitable lands where people can produce food and energy simultaneously.

2) Overcoming the problem of traditional PV power generation

- Agrivoltaic systems can help to overcome the problem of limited land resources, negating this disadvantage of PV power generation.

- Limitations related to the installation area are one disadvantage of traditional PV power generation: This is less important for households, where PV modules installed on rooftops can generate sufficient electricity, but industry requires a huge area for PV power plants to provide a sufficient and constant electricity supply.

3) Supplementation of agrivoltaic systems

· Battery backup systems

- The system cannot adequately function if sunlight is not available during the night or on cloudy days : Thus, it is difficult to rely on agrivoltaic systems as a main power source even if the total generation capacity is large enough to meet a country’s electricity demand.

- The key to solving this is to employ battery backup systems that can store electricity for use when sunlight is not available.

· PV Panel Recycling

- Although PV power generation itself does not cause pollution, the disposal of PV panels may have serious impacts on the environment. The impact could be particularly serious if agrivoltaic systems are adopted for large areas of farmland, resulting in huge volumes of PV panels requiring disposal.

- It is necessary to develop effective methods for recycling large volumes of PV panels while also promoting agrivoltaic systems./h6>

4) Reference

식량과 청정 에너지 생산을 위한 에너지 공유 : 전형적으로 음지에서 성장이 어려운 작물, 옥수수를 통해 확인한 영농형 태양광 시스템 성과

[Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic systems for Corn, A Typicla Shade-intolerant Crop]

4.World leading countries in solar sharing technology

1) Japan

- Solar power generation came to Japan in the year 1993.: For 20 years, one of the changes that has come about in the field of solar energy is Agricultural Solar Sharing (also known as agrophotovoltaics (APV) or agrivoltaics).

- In 2013, there was only about 100 developments. By the year 2017 there was about 1,300 developments.Currently the most solar sharing projects are in Chiba prefecture, with Shizuoka prefecture having the second most, and Gunma prefecture has the third most.

2) Germany

- Since 2016, the dual use of land for the harvesting of solar electricity and agriculture has been tested

- Integrated Photovoltaic Solutions presented at the EU PVSEC 2019 by Fraunhofer ISE

* Meeting Germany’s climate protection targets will require a significant expansion of photovoltaics.

* Integrating PV technology into building envelopes, vehicles and roads, as well as over agricultural fields and floating on water surfaces, capitalizes on surface areas with a tremendous potential for generating solar power.

* In Germany, building-integrated solar technologies and agrophotovoltaics alone can offer several hundred gigawatts of power.

- On one-third of a hectare arable land near Lake Constance in Germany, photovoltaic modules with a total power output of 194 kilowatt are installed on a five-meter-high structure.

- The results from 2017 showed a land use efficiency of 160 percent, as confirmed by the project consortium.

- The performance of the agrophotovoltaic system in the very hot summer of 2018 greatly exceeded this value.: Based on the 2018 potato yield, the land use efficiency rose to 186 percent per hectare with the agrophotovoltaic system -by Stephan Schindele of Fraunhofer ISE

· Scientists of the University of Hohenheim collected data on the climatic conditions underneath the APV system and also from the neighboring reference field.

- The solar irradiation underneath the APV system was about 30 percent less than the reference field. In addition to the amount of solar irradiation, the APV system affects the distribution of precipitation and the soil temperature.

- In spring and summer, the soil temperature under the APV system was less than on the reference field; the air temperature was identical.

- In the hot, dry summer of 2018, the soil moisture in the wheat crop was higher than the reference field, while in the winter months, it was less.

* The shade under the semi-transparent solar modules enabled the plants to better endure the hot and dry conditions of 2018 -the agricultural scientist Andrea Ehmann

* This result shows the potential for APV in arid regions.

- The electricity production costs of an APV system is today competitive with a small PV rooftop system. Researchers anticipate further cost reductions due to economies of scale and learning effects.

- If the electricity is stored and used on site, as at the farm community Heggelbach, additional sources of income arise due to synergy effects.

- When politics allow, agrophotovoltaics can provide the answer to the “food or fuel” debate. From the technical point of view, farmers can harvest both.

- Through the dual use of arable land, the main task of food production is met. The additional solar electricity production contributes to the expansion of electric mobility and serves to protect the climate.

- When politics allow, agrophotovoltaics can provide the answer to the “food or fuel” debate. From the technical point of view, farmers can harvest both.

- Through the dual use of arable land, the main task of food production is met. The additional solar electricity production contributes to the expansion of electric mobility and serves to protect the climate.

- Shade from the panels protects against overheating and global warming, also keeps the earth humid.

- This system enables people to generate electricity on farmland, pasture land, water surfaces, roads, and anywhere people, animals, and plants are living.

- Even barren deserts can be changed into habitable lands where people can produce food and energy simultaneously.

- Limitations related to the installation area are one disadvantage of traditional PV power generation: This is less important for households, where PV modules installed on rooftops can generate sufficient electricity, but industry requires a huge area for PV power plants to provide a sufficient and constant electricity supply.

- The key to solving this is to employ battery backup systems that can store electricity for use when sunlight is not available.

- It is necessary to develop effective methods for recycling large volumes of PV panels while also promoting agrivoltaic systems./h6>

4) Reference

식량과 청정 에너지 생산을 위한 에너지 공유 : 전형적으로 음지에서 성장이 어려운 작물, 옥수수를 통해 확인한 영농형 태양광 시스템 성과[Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic systems for Corn, A Typicla Shade-intolerant Crop]